Automotive industry

Structural elements for buses

Products for the interiors of buses are made using lamination technology. We produce exterior and interior components for our customers.

|

|

|

|

|

|

|

|

|

|

|

|

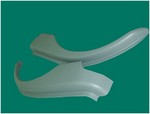

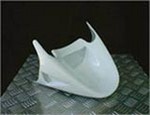

Accessories for passenger vehicles and lorries

Products for passenger vehicles include e.g. the fibreglass superstructure for the Excelsion EVO2. It is produced using high quality composite materials, which ensure its strength, shape stability and non-corrosiveness.

The fibreglass spoiler for the Excelsion EVO2 is also made from the same materials as the superstructure. No interventions to the vehicle body are required to install the spoiler, which is sealed using a special bonding agent along its perimeter.

|

|

|

|

|

|

|

|

Vehicle accessories:

|

|

|

|

|

|

|

|

Accessories for trailers and equipment:

|

|

|

|

|

|

|

|

Renovation of ferry thanks, cover parts of cleaning equipment:

|

|

|

|

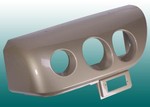

Products made from thermoplastics for the automotive industry

Vacuum moulding is a technology for the thermal processing of thermoplastics. The production process is based on the fastening of pre-cut sheets or foils into the frame of the vacuum press, heating it to the temperature for shaping and then shaping the part using vacuum. For the production of parts using vacuum moulding technology, it is possible to use plates and foils made from copolymer ABS, polyethylene, polycarbonate, polymethyl methacrylate, polypropylene (also reinforced with glass fibres or fillers) and polyvinyl chloride.

|

|

|

|

|

|

|

|

|

|

|

|

Structural elements for two-wheelers

In the field of two-wheelers, we supply laminate parts for various prototypes of road motorbikes.

|

|

|

|

|

|

|

|

Are you interested in structural elements for the automotive industry? Contact us!

© 2025 FORM s.r.o.

Created by eBRÁNA s.r.o. | Powered by CMS WebArchitect | SEO a internetový marketing