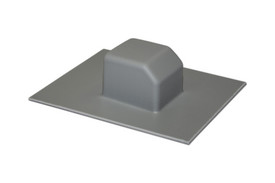

Vacuum moulding

We ensure customized and batch production of parts using the technology of vacuum moulding thermoplastics for the automotive and rail industries. The advantages of this method include the low cost of manufacturing production moulds.

Vacuum moulding is a technology of thermal processing thermoplastics. The production process is based on the fastening of pre-cut sheets or foils into the frame of the vacuum press, heating them to the temperature for shaping and then shaping the part using vacuum.

For more information about the technological possibilities of production, contact us. Contact us with more detailed requirements and we will immediately send you a price offer free of charge.

Products made from thermoplastics according to your wishes

After consultation we will provide technical documentation, then 3D visualization and upon your approval we will prepare the production mould for moulding thermoplastics. The entire process right until the final delivery takes several weeks, depending on the complexity of the model.

Based on your requirements we will recommend a thermoplastic to you (ABS, polycarbonate and polymethyl acrylate …) that is suitable for your specific needs. We are able to deliver material that is resistant to chemicals, with increased resistance to fire, special surface treatment, etc.

Thermoplastics are distinguished by the excellent chemical and mechanical properties, shape consistency and tenacity.

Why leave the production of thermoplastics to FORM?

· 20 years of experience

· We are holders of the ISO 9001:2008 certificate.

· On your request, we can apply your logo to the thermoplastic mouldings

· After pressing, we can also provide CNC machining and painting materials

· We will deliver the finished products on pallets all the way to your doorstep

We supply products made form thermoplastics to large car manufacturers such as Škoda Auto.

Contact form

© 2025 FORM s.r.o.

Created by eBRÁNA s.r.o. | Powered by CMS WebArchitect | SEO a internetový marketing